Tempered Glass,Toughened Glass, Prestressed glass, Reinforced glass

Product Description

Tempered glass/Reinforced glass is a type of safety glass. Toughened glass is actually a kind of prestressed glass, in order to improve the strength of glass, usually use chemical or physical methods, the formation of compressive stress on the surface of glass, glass under external force first offset surface stress, so as to improve the bearing capacity, enhance the glass itself resistance to wind pressure, heat and cold, impact, etc.

⒈ Physical tempered glass is also known as hardened tempered glass. It is the ordinary plate glass in the heating furnace heating to close to the softening temperature of the glass (600℃), through its own deformation to eliminate the internal stress, and then the glass out of the heating furnace, and then use a multi-head nozzle to blow the high pressure cold air to both sides of the glass, so that it is rapidly and evenly cooled to room temperature, toughened glass can be made. This kind of glass in the internal tension, external pressure stress state, once the local damage, will occur stress release, glass is broken into numerous small pieces, these small pieces without sharp edges and corners, not easy to hurt.

Chemical tempered glass is to improve the strength of glass by changing the chemical composition of the surface of the glass, which is generally tempered by ion exchange method. The method is to contain alkali metal ions of silicate glass immersed into the molten state of lithium salt, so that the glass surface Na or K ion and lithium ion exchange, the surface of the formation of lithium ion exchange layer, due to the expansion coefficient of lithium is less than Na or K ion, resulting in the cooling process of the outer shrinkage and the inner shrinkage of the larger. When cooled to room temperature, the glass is also in a state of inner tension, outer pressure, the effect is similar to physical toughened glass.

Matters need attention:

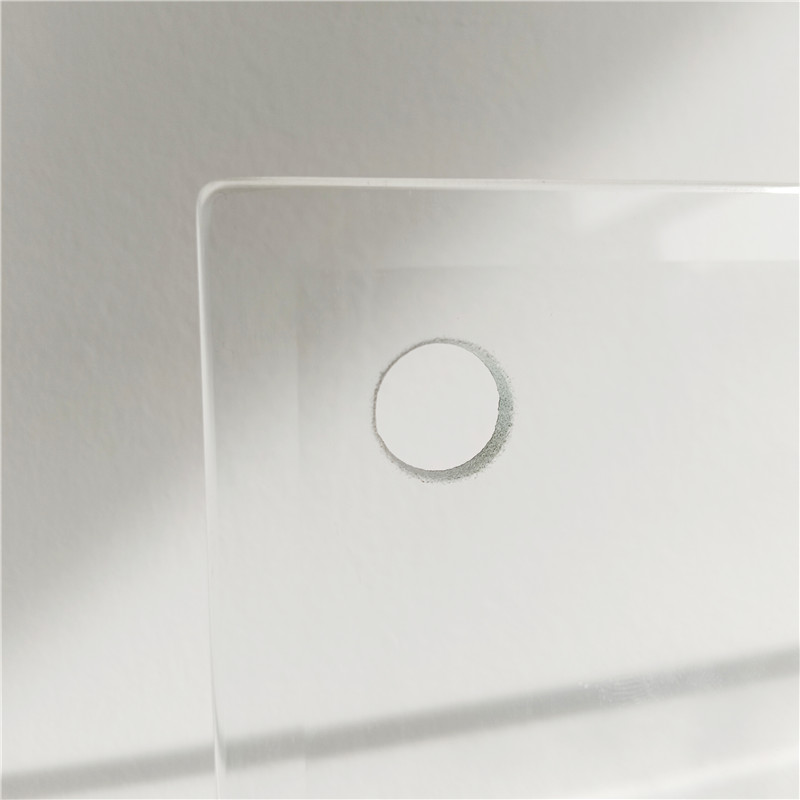

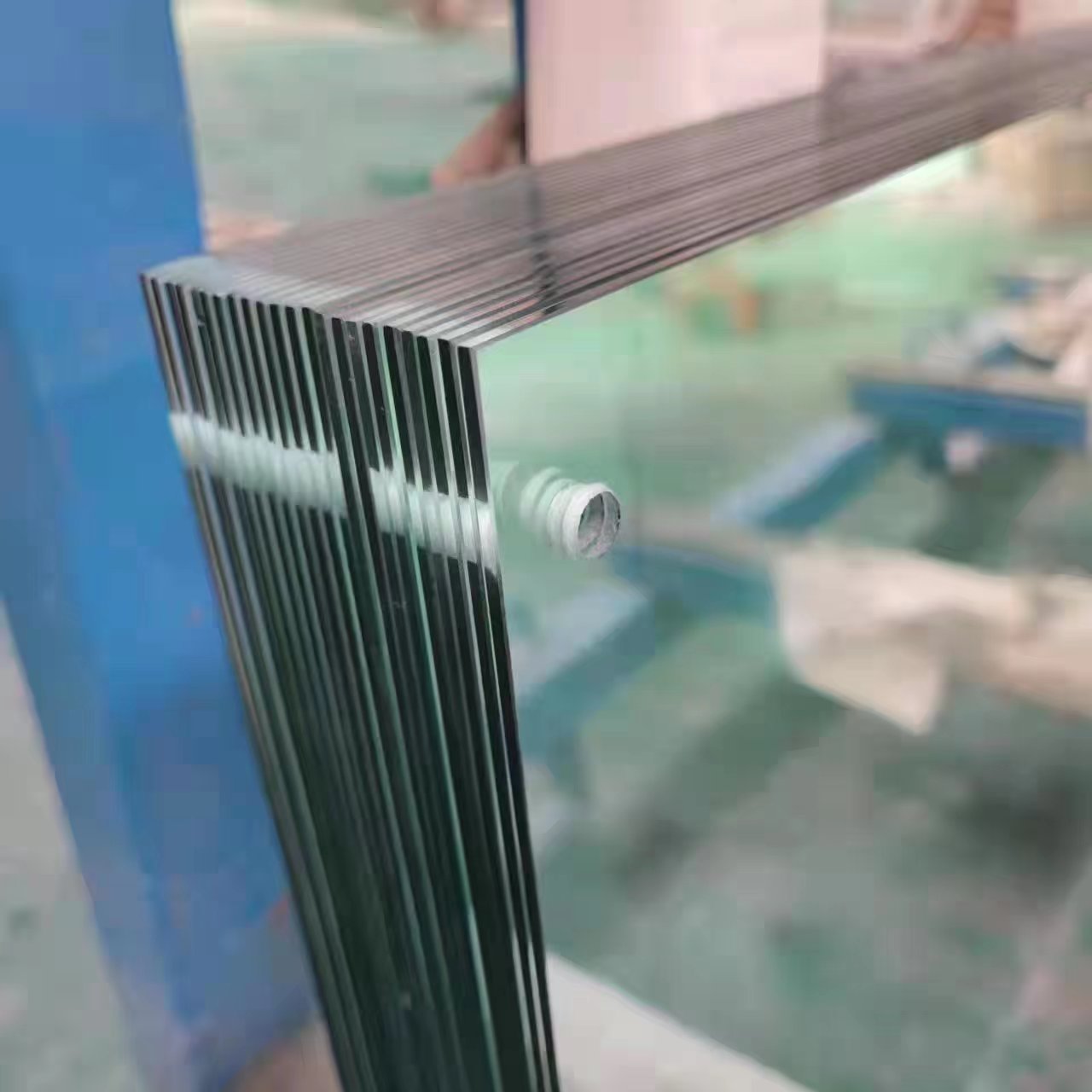

Cutting, drilling and edging of glass must be completed before tempering.

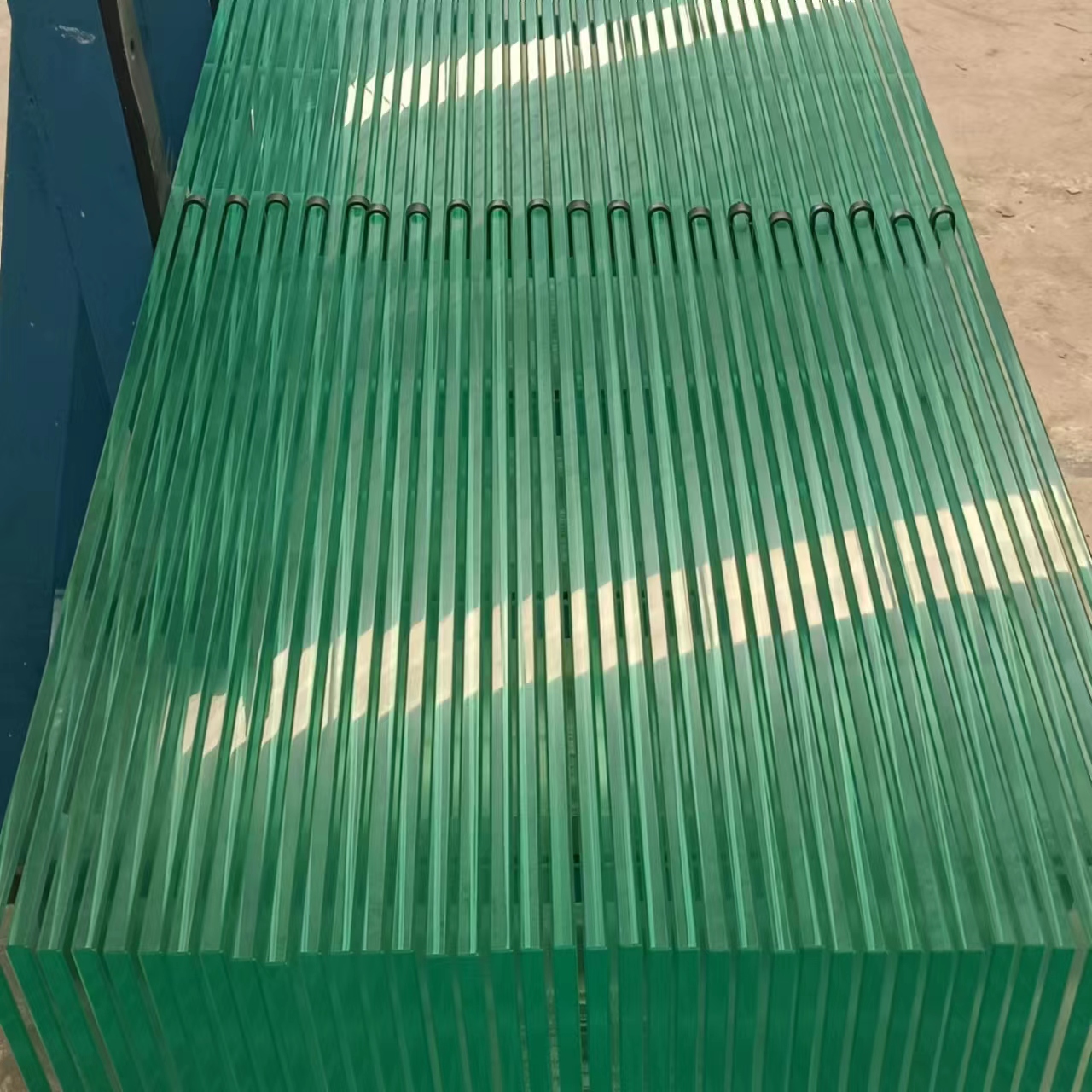

Products should be packed in containers or wooden cases. Each piece of glass shall be packed in a plastic bag or paper, and the space between the glass and the packing box shall be filled with light soft materials that are not likely to cause appearance defects such as scratches on the glass. The specific requirements shall conform to the relevant national standards.

Benefits

Security

When the glass is destroyed by external forces, the fragments will become honeycomb like obtuse small particles, not easy to cause serious harm to the human body.

High strength

The impact strength of tempered glass of the same thickness is 3 ~ 5 times that of ordinary glass, and the bending strength is 3 ~ 5 times that of ordinary glass.

Thermal stability

Toughened glass has good thermal stability, can withstand the temperature difference is 3 times that of ordinary glass, can withstand the temperature change of 300℃.

Applications

Flat tempered and bent tempered glass belongs to safety glass. Widely used in high-rise building doors and Windows, glass curtain walls, indoor partition glass, lighting ceiling, sightseeing elevator passage, furniture, glass guardrail, etc. Usually tempered glass can be used in the following industries:

1. Construction, building form work, decoration industry (example: doors, Windows, curtain walls, interior decoration, etc.)

2. Furniture Manufacturing Industry (glass tea table, furniture, etc.)

3. Household appliance manufacturing industry (TV, oven, air conditioning, refrigerator and other products)

The electronic and meter industries (a variety of digital products such as mobile phones, MP3 players, MP4 players and clocks) have done this.

4. The automobile manufacturing industry (automobile window glass, etc.)

Pictures of daily product industry (glass chopping board, etc.)

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top