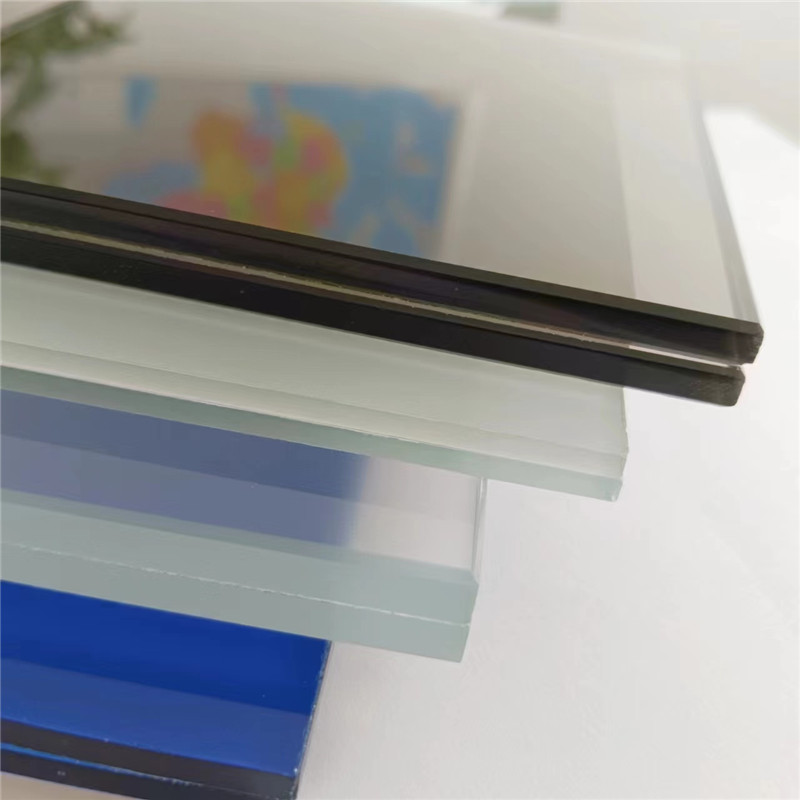

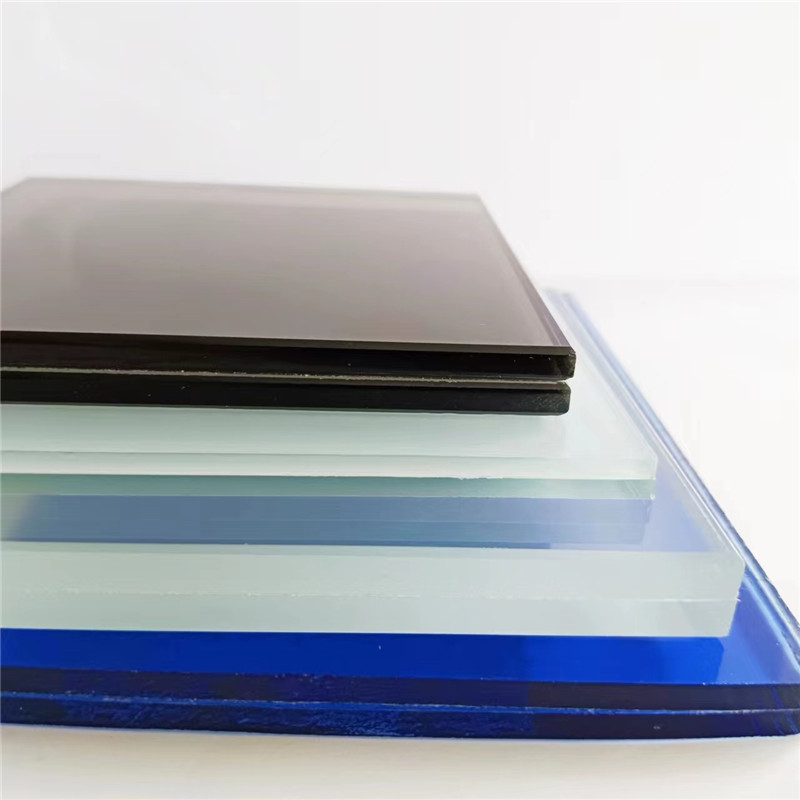

Laminated Glass,Tinted Laminated Glass, PVB Glass

Product Display

Product Description

Two or three layers of clear float glass "sandwiched" together with clear or colored PVB interlayer, laminated glass is the one glass that reconciles the aesthetic benefits of glass with a genuine concern for safety;

Two or several pieces of float glass sandwiczed with a strong PVB (vinyl polymer butyrate) film, the hot press combined to discharge the intermediate air as far as possible, and then into the high-pressure steam tank using high temperature and high pressure will be a small amount of residual air dissolved into the film. For the convenience of customers and designers higher requirements, can provide a variety of PVB film for customers to choose (transparent, milky white, dot and customer specified color).Commonly used laminated glass intermediate film are: PVB, SGP, EVA, PU and so on. In addition, there are some more special, such as color inter film laminated glass, SGX type printing inter film laminated glass, XIR type LOW-E inter film laminated glass, etc. Embedded decorative pieces (metal mesh, metal plate, etc.) laminated glass, embedded PET material laminated glass and other decorative and functional laminated glass. The intermediate film itself can also absorb the impact energy, with anti-theft, bulletproof, reduce noise and anti-ultraviolet, fire resistance function, but also according to the need of sandwich glass and various functions of the intermediate film, the formation of a variety of performance laminated glass, in order to meet the needs of modern life.

Laminated safety glass is commonly used for automotive windshields, but the safety benefits are applicable to the household too. A table top made from laminated glass would be a perfect fit in a household with children.offering superior protection against glass breakage, as well as harmful solar rays and hazardous noise levels.

Due to the adhesive properties of the PVB, takes careful precautions to prevent unwanted particles from attaching to the PVB during the adhesion process.

Benefits

Holds together when shattered. The PVB interlayer keeps the glass bonded, even when broken, resulting in a characteristic spider web cracking pattern across the glass.

Cyclone resistant

Superior UV blockage

Excellent sound damping properties

Low visible distortion

Applications

External use of windows, doors, shopfronts in offices, houses, shops etc.

Interior glass screens, partitions, balustrades etc.

Shop display windows, showcases, display shelves etc.

Furniture, table-tops, picture frames etc.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top