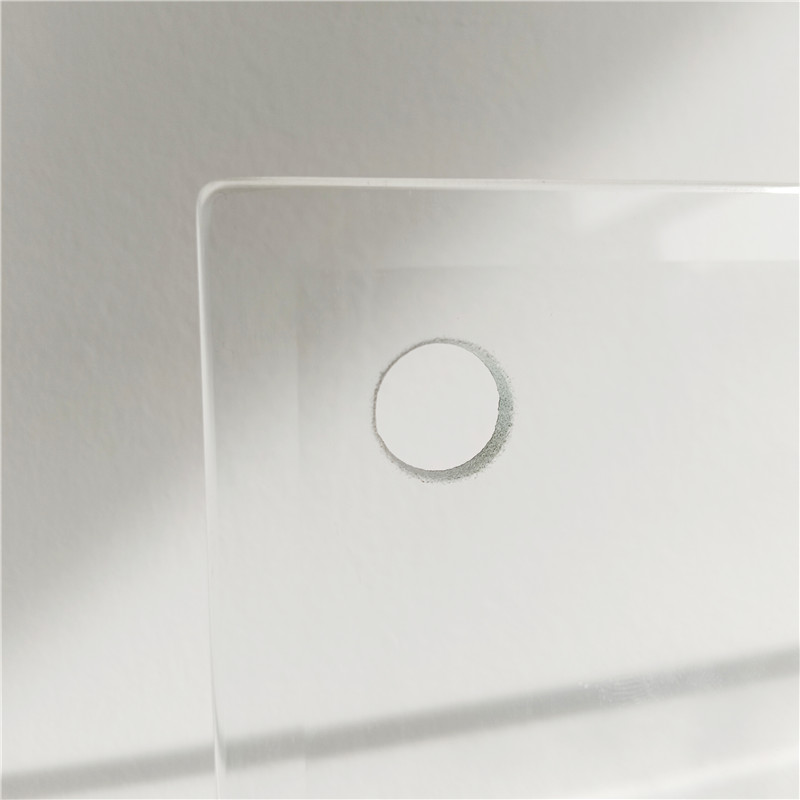

Laminated Glass,Safety Glass,Composite Glass

First, the name of laminated glass

Laminated glass, also known as safety glass, laminated glass, is a composite safety glass made of two or more layers of glass sheets intercalated with PVB film. The name of Laminated Glass varies according to different regions, such as in Europe and the United States, laminated glass is generally called Laminated Glass, and in China, laminated glass is also called composite glass, safety glass and so on.

Second, the structure of laminated glass

Laminated glass mainly consists of the following three parts:

1. Glass sheet: laminated glass is composed of two or more glass sheets, and the type and thickness of glass sheets are determined according to the required level of protection and application environment.

2.PVB film: PVB film is a kind of plastic film in the middle layer of laminated glass, the specific gravity and hardness are smaller than that of glass, which can absorb the impact energy well and enhance the explosion-proof, seismic and sound insulation performance of laminated glass.

3. Interlayer: Interlayer is the glue layer that binds PVB film and two or more pieces of glass together, and the thickness of interlayer can be customized according to the safety requirements and application environment requirements, the most common thickness is 0.38mm and 0.76mm.

Laminated glass varies in structure and thickness, allowing it to adapt to a variety of complex design and safety needs.

Third, the performance of laminated glass

Laminated glass is a high performance safety glass, with the following aspects of performance:

1. Explosion-proof performance: The PVB sandwich of laminated glass can absorb the impact force of the human body and objects, and disperse it to the entire glass surface, so as to effectively prevent the glass from breaking and generating debris, so as to achieve the purpose of explosion-proof.

2. Anti-theft performance: laminated glass is not easy to be damaged or cut, even if the laminated glass is damaged, it will not completely break, thereby increasing the anti-theft performance of the window.

3. Seismic performance: the PVB sandwich of laminated glass can absorb energy during an earthquake, reduce the vibration and fragmentation of the glass, and help suppress the spread of sound.

4. Sound insulation performance: the PVB sandwich of laminated glass can effectively isolate sound transmission, greatly reducing the difference between indoor and outdoor sound and improving indoor comfort.

5. Heat insulation performance: the PVB sandwich of laminated glass can effectively prevent the transmission of ultraviolet light and the loss of heat, which is especially important for places that need to maintain temperature stability.

In summary, laminated glass, as a kind of safety glass, has strong protective properties and a wide range of applications. I hope that through the introduction of this article, we have a deeper understanding of laminated glass.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top