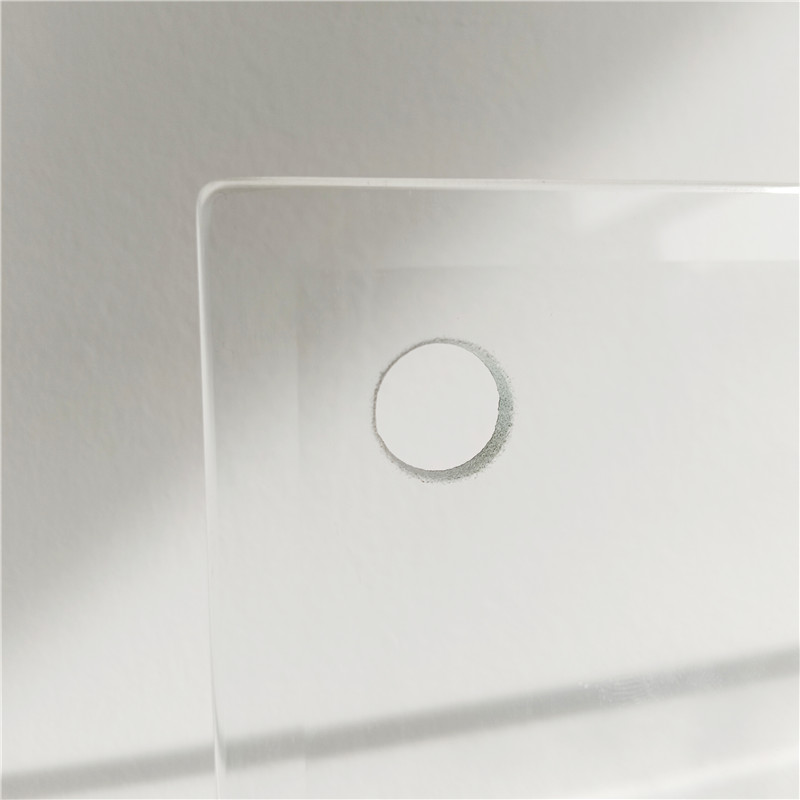

Coated Laminated Glass For Stair Railing ,Balcony Railing

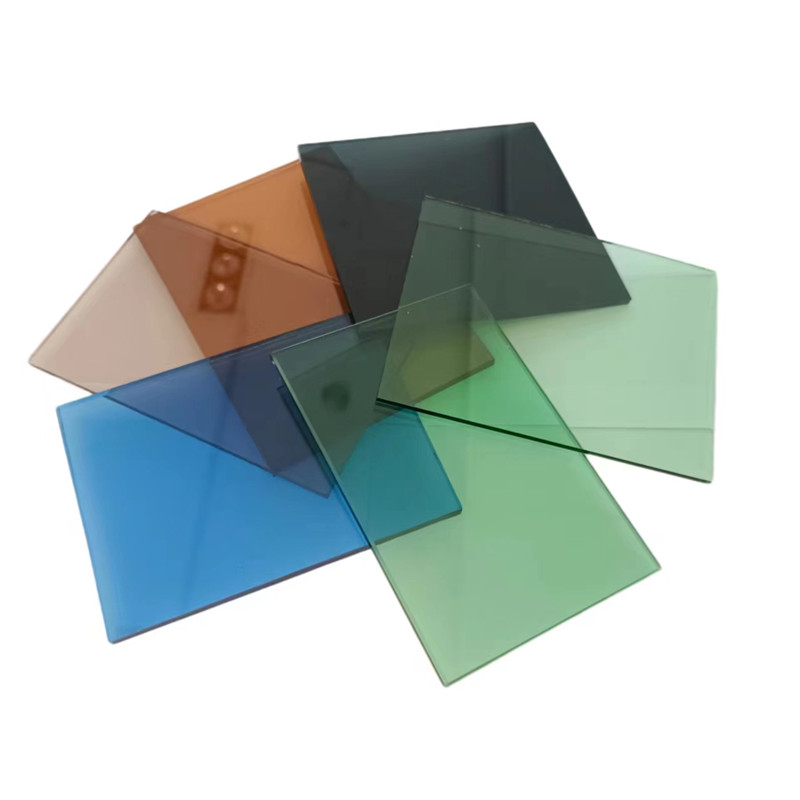

Glass materials come in various varieties, with superior performance and high quality. They can not only be used as decoration, but are also durable and have a wide range of functions. Glass partitions and car windows must be made of glass. Smooth, pure and bright, it is needed in all walks of life. Glass is a popular decorative material nowadays and is used in building interior decoration and outdoor glass curtain walls. Glass coating methods and glass lamination technical process.

1. Why should glass surface be coated?

Glass coating is to apply one or more layers of metal films or metal compounds on the surface of the glass to change the optical properties of the glass.

There are many production methods for coated glass, including vacuum magnetron sputtering, vacuum evaporation, chemical vapor deposition and sol-gel method. Magnetron sputtering coated glass uses magnetron sputtering technology to design and manufacture multi-layer complex film systems. It can plate a variety of colors on a white glass substrate. The film layer has good corrosion resistance and wear resistance, and is the ideal choice for production and use. One of the more products. There is a certain gap between the variety and quality of vacuum evaporation coated glass and magnetron sputtering coated glass, and it has been gradually replaced by vacuum sputtering. The chemical vapor deposition method is to introduce reactive gases in the float glass production line to decompose on the hot glass surface, and evenly deposit on the glass surface to form coated glass. This method is characterized by low equipment investment, easy control, low product cost, good chemical stability, and can be thermally processed. It is one of the more promising production methods. The sol-gel method for producing coated glass has a simple process and good stability. The disadvantage is that the light transmittance of the product is too high and the decorative properties are poor.

2. Technical process of glass lamination process

There are two types of lamination: PVB lamination and EVA lamination.

PVB lamination requires a series of equipment such as autoclaves, roller presses, and film washers. The capital investment cost is relatively high. A smaller autoclave costs RMB 400,000 to RMB 50,000. The autoclave mainly includes cleaning, laminating, pre-pressing, and Cauldron four steps.

Principle: Not much to say about cleaning and joining. The pre-pressure is to compress the air between the two pieces of glass and the middle PVB into small bubbles through a roller press, so that the two pieces of glass are adhered together through the PVB; entering the kettle is under high pressure The bubbles are compressed in the kettle until they are invisible to the naked eye through more than ten atmospheric pressures. It is characterized by relatively high strength. It is mainly used for automobile front windshields, etc.

EVA lamination only requires a lamination furnace, which mainly includes cleaning, lamination, and furnace feeding.

The principle is to pre-extract the air between the two pieces of glass through a vacuum pump to form a vacuum state in the silicone bag, and then enter the furnace to melt the EVA film at high temperature to bond the two pieces of glass together. It is characterized by bonding EVA film has relatively good strength and good light transmittance. The characteristic of EVA film is that the investment cost is relatively low, and the equipment is about 100,000 units. It is mainly used in architectural glass, such as curtain walls, lighting roofs, awnings and other laminated glass.

YAOTAI is a professional glass manufacturer and glass solution provider include range of tempered glass,laminated glass, reflective glass,float glass,mirror,Door and window glass, furniture glass, embossed glass, coated glass,textured glass and etched glass. With more 20 years development,there are two produce lines of pattern glass,two lines of float glass and one line of restoration glass. our products 80% ship to overseas,All our glass products are strict quality control and carefully packed in strong wooden case,ensure you receive the finest quality glass safety in time.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

Top